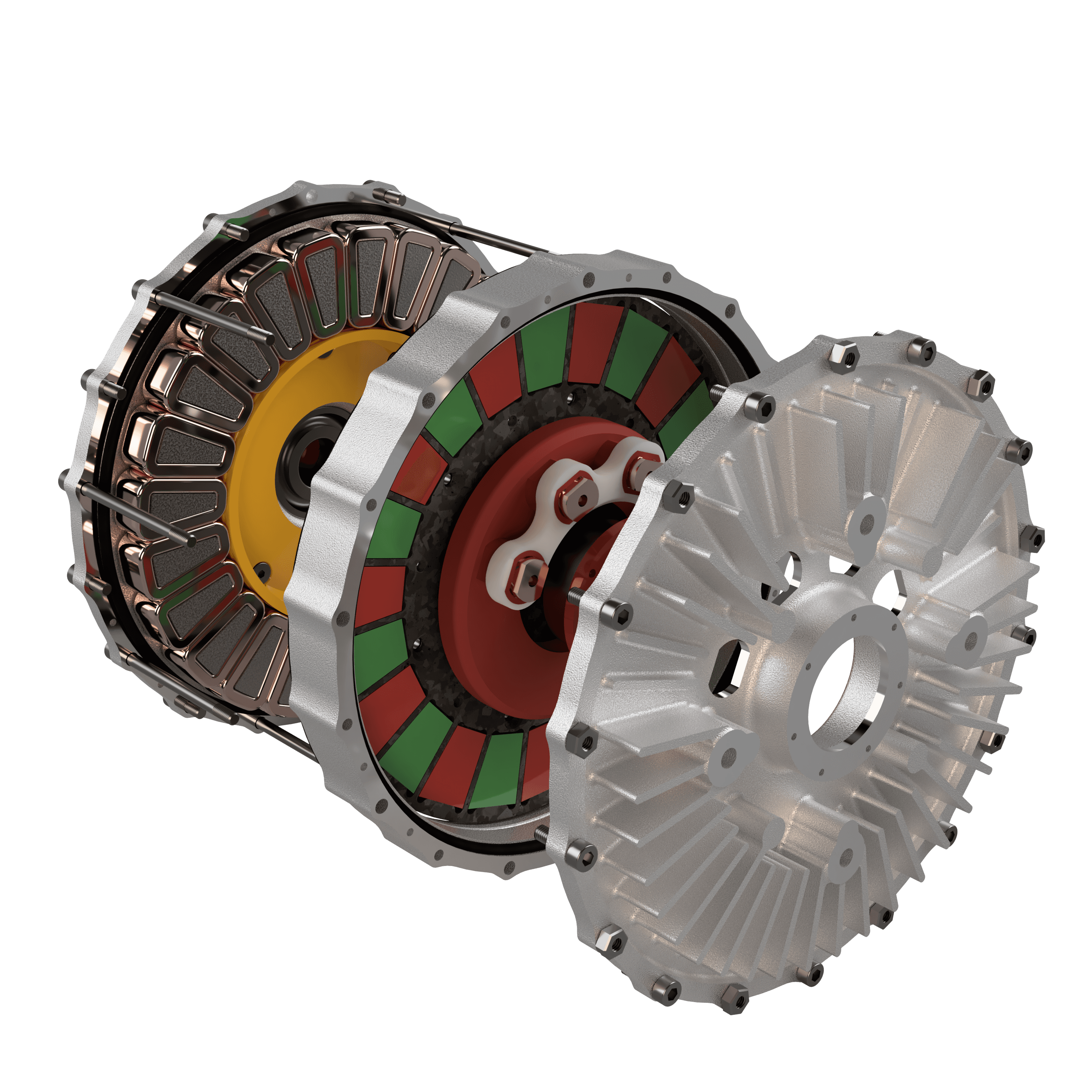

Thinnest Axial Flux Motors on the market

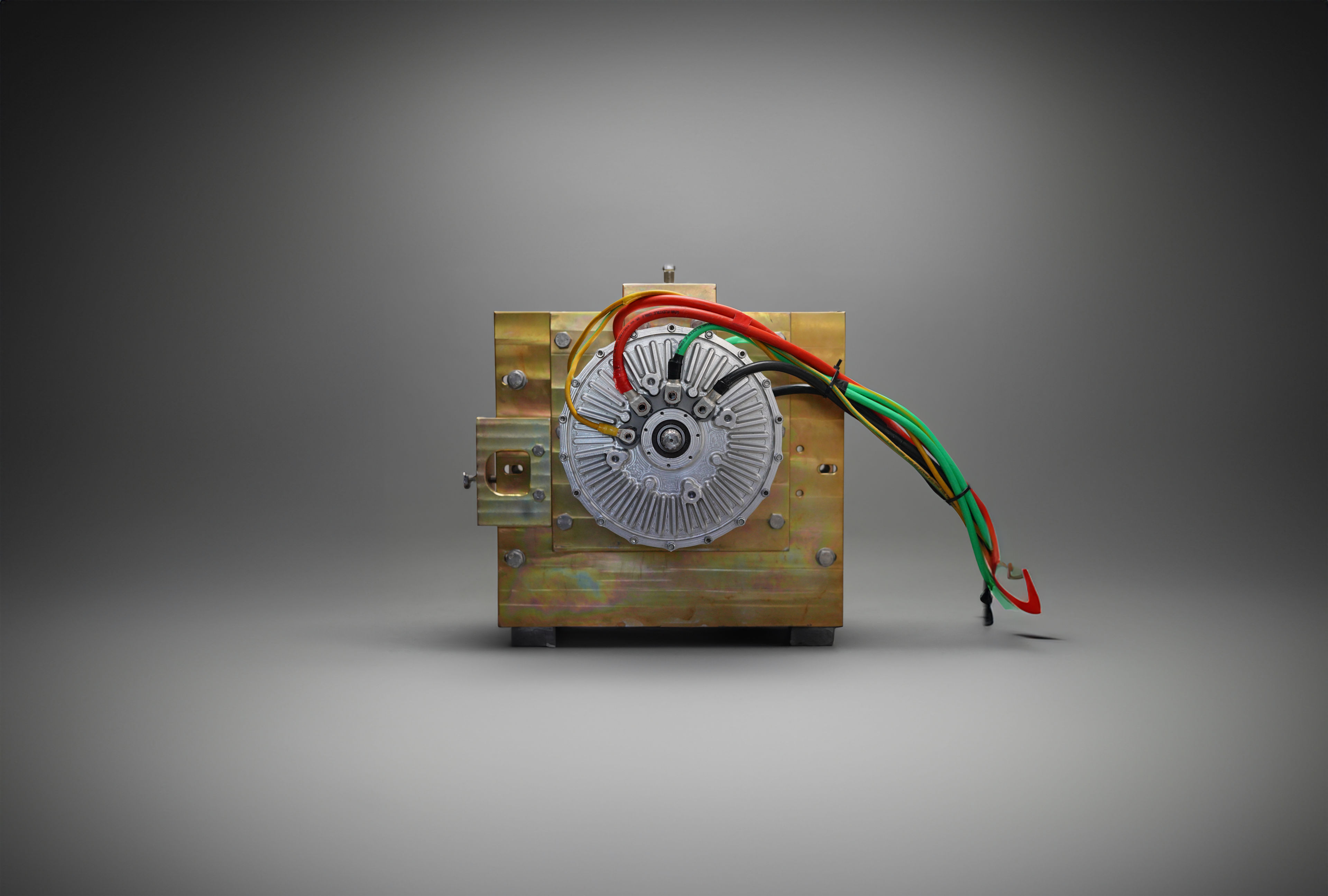

WX 70-A

Ideal where space is tight

✓ Brushless synchronous Axial Flux Motor technology.

✓ Delivers outstanding power density and efficiency.

70 mm axial height

Air Cooled

Torque Range: 3.4 - 20 Nm

Max Speed: 6000 rpm

WX 70-W

Ideal where space is tight

✓ Brushless synchronous Axial Flux Motor technology.

✓ Delivers outstanding power density and efficiency.

70 mm axial height

Water Cooled

Torque Range: 6.2 - 23 Nm

Max Speed: 6000 rpm

WX 90-A

Ideal for torque applications

✓ High-performance brushless synchronous Axial Flux Motor technology.

✓ Engineered for exceptional power density and efficiency.

90 mm axial height

Air Cooled

Torque Range: 12 - 42 Nm

Max Speed: 6000 rpm

WX 90-W

Ideal for torque applications

✓ High-performance brushless synchronous Axial Flux Motor technology.

✓ Engineered for exceptional power density and efficiency.

90 mm axial height

Water Cooled

Torque Range: 20.6 - 44 Nm

Max Speed: 6000 rpm

RAPID MOTOR DELIVERY IN ONLY 2 MONTHS

We work closely with customers and provide hands-on support to ensure the first motors are delivered in under 2 months.

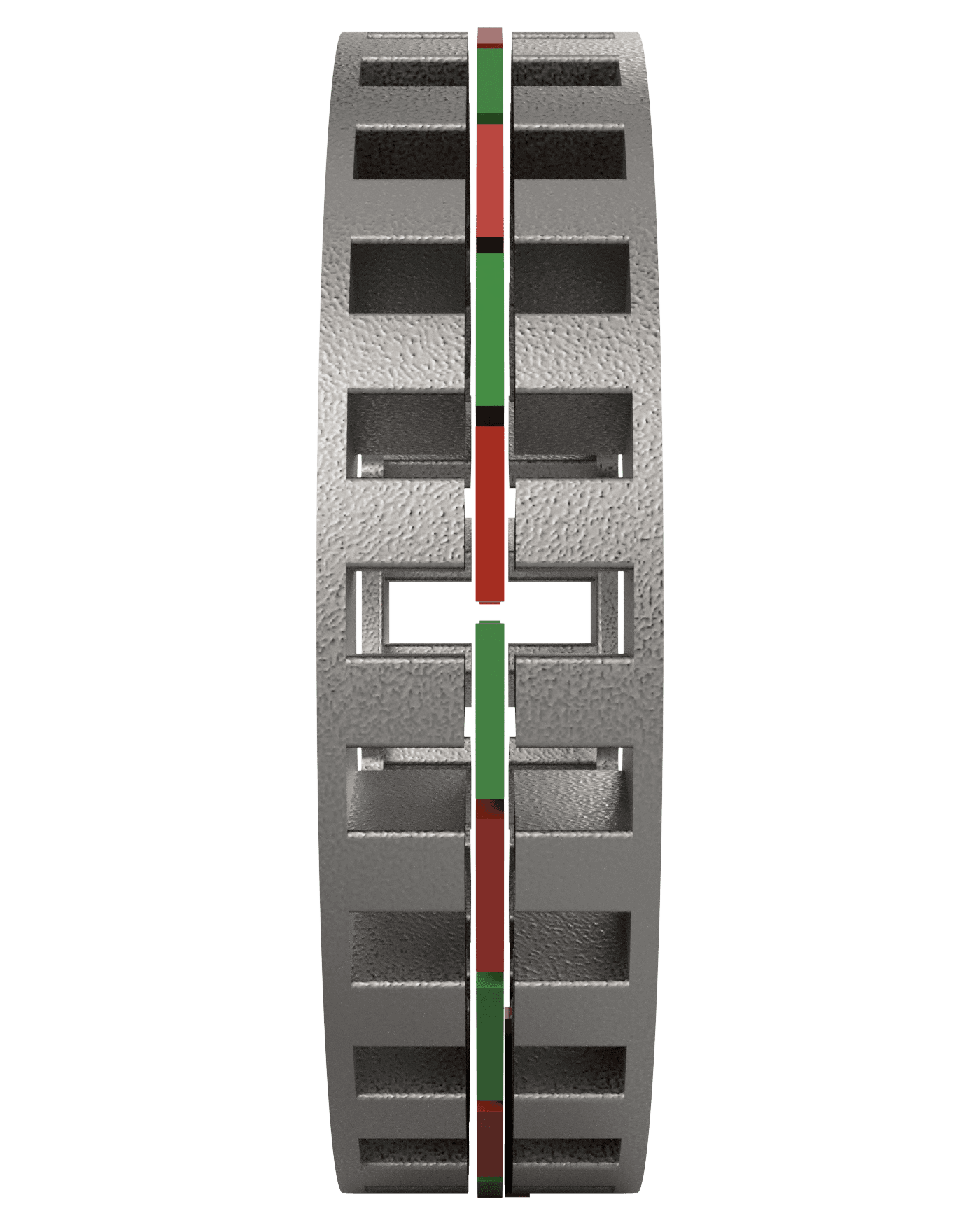

WHEEMX AI-DRIVEN MOTOR INNOVATION

Designed by our AI-enhanced simulation tool WheemX, we've engineered the most efficient motors on the market, optimised for peak performance.

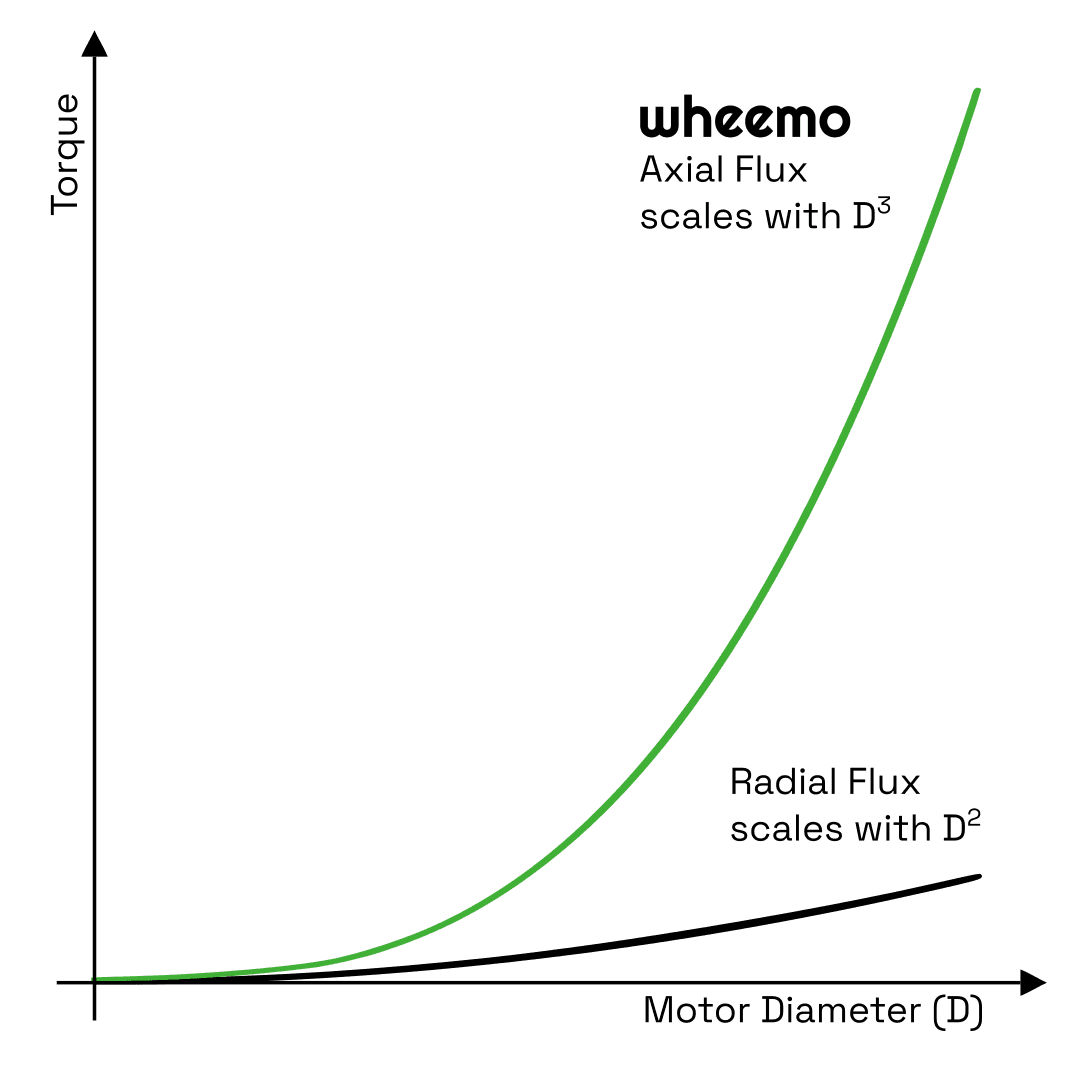

MOST TORQUE-DENSE MOTOR ON THE MARKET

Wheemo delivers unmatched torque density, empowering your application with the maximum force in the most compact package.