At Wheemo, we specialise in high-performance, customised Axial Flux Motors for the aerospace, automotive, marine, and industrial sectors. Using our proprietary WheemX™ design platform, we generate optimised solutions precisely tailored to your specific requirements for performance, cost, and size.

This flexible, data-driven approach enables the rapid development of bespoke prototypes through to scalable production units, delivering a motor perfectly engineered for your application.

From concept to delivery

From concept to delivery

Defining Requirements

Defining Requirements

In-depth analysis of requirements, where goals and efficiency objectives are defined.

Prototype Motor

Building, testing and iterating customised axial flux motor for optimal performance.

Design and Simulation

Simulation and design iterations undertaken with our customer to determine optimal geometry using WheemX.

Production Motor

Delivering your Axial Flux Motor within 3 to 6 months for you to test.

Contact us for a quote

Contact us for a quote

Contact us for a quote

Why Axial Flux Technology

HIGHER TORQUE AND POWER DENSITY IN A MORE COMPACT PACKAGE

The axial flux technology is reshaping the landscape of electric motors. Even with improved material usage, it outperforms radial flux motors, making it an ideal choice where packaging and performance matters.

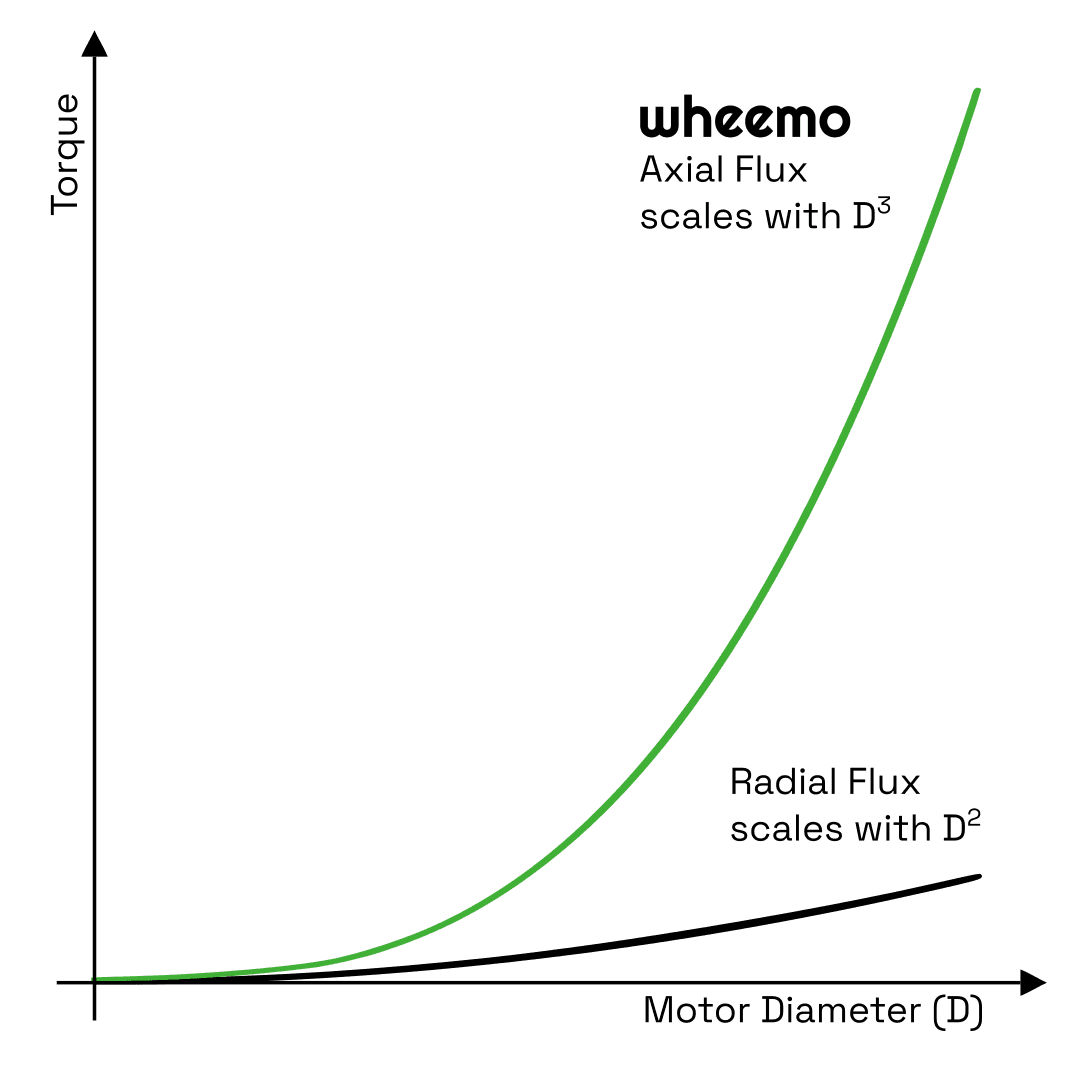

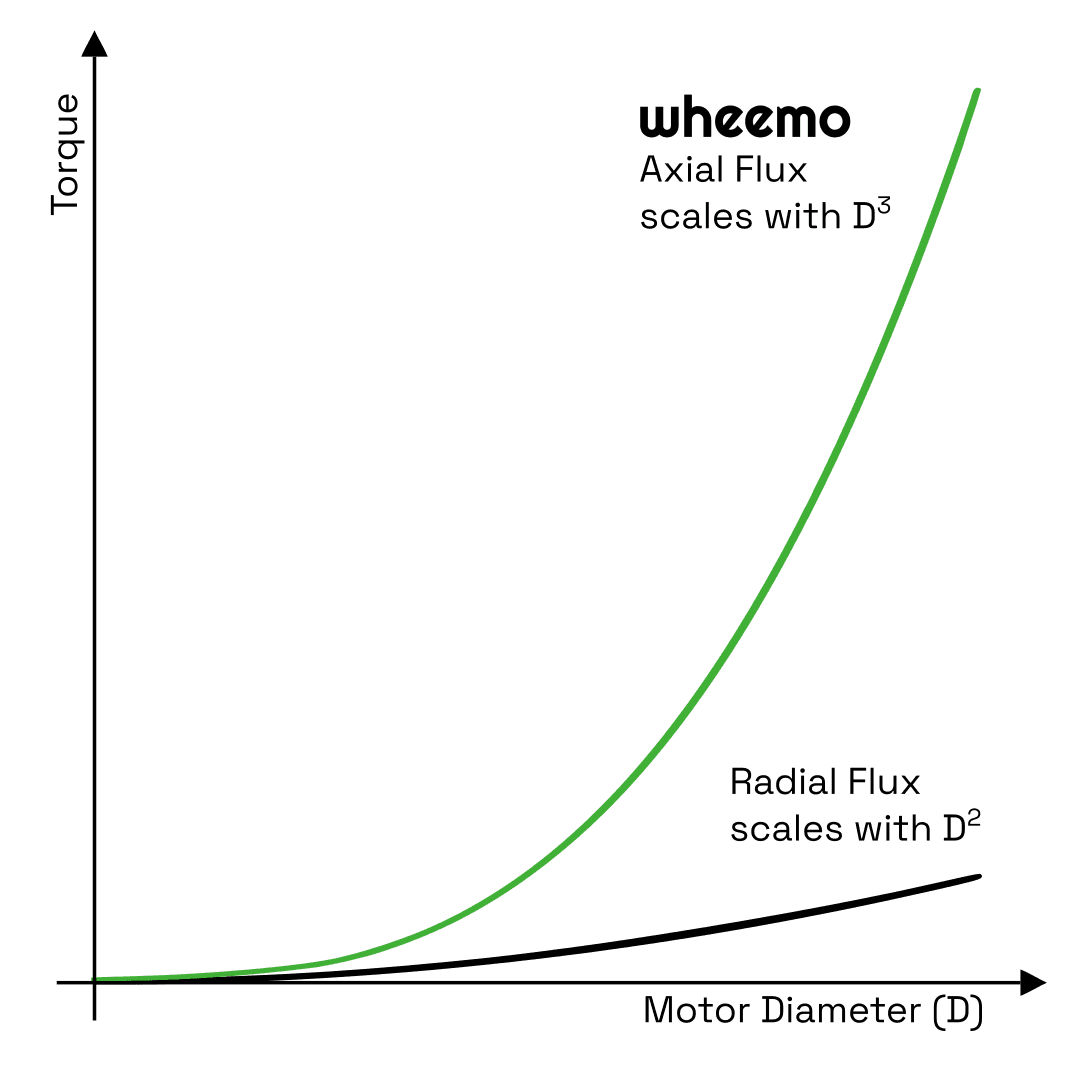

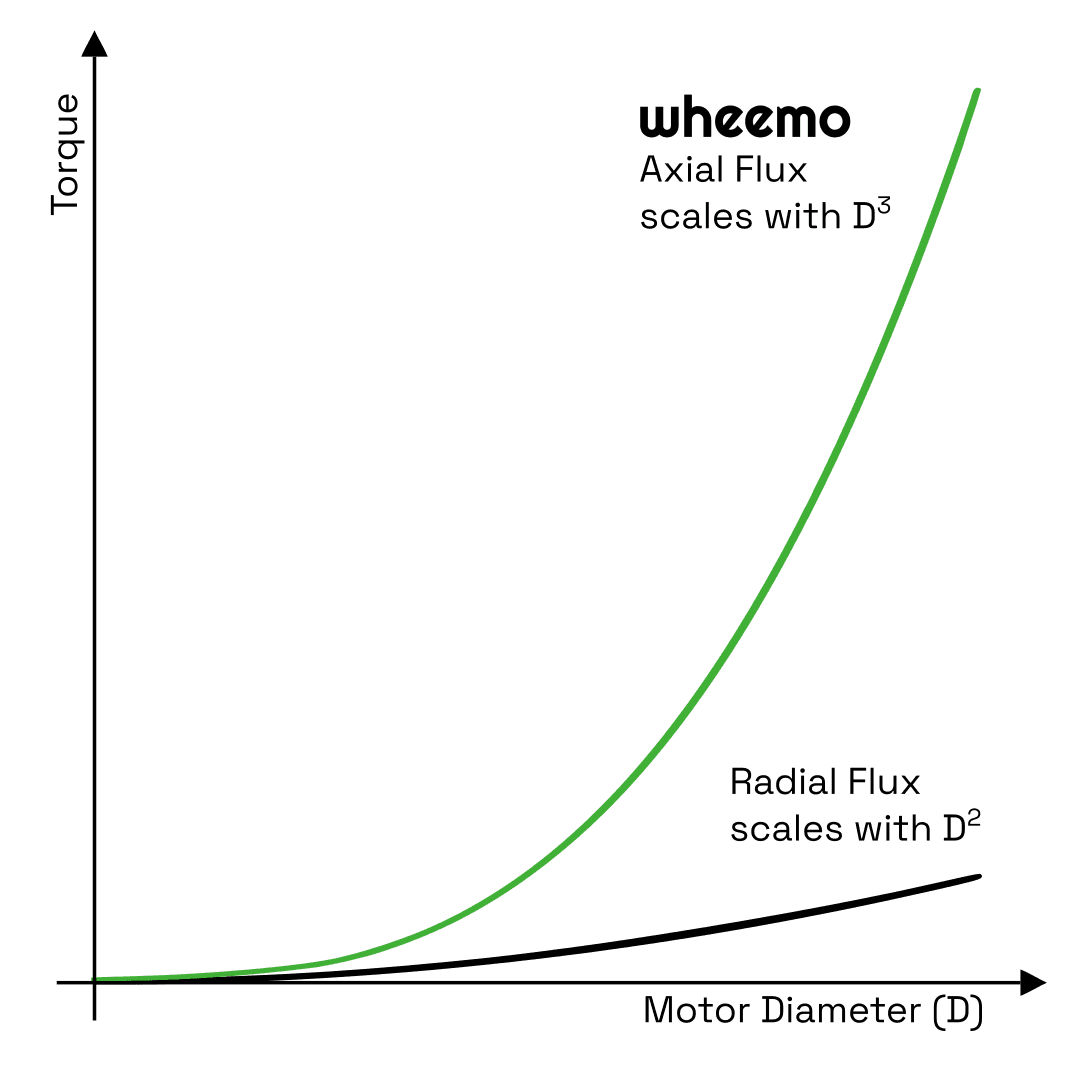

PERFORMANCE INCREASES MUCH MORE WITH ROTOR DIAMETER

Axial flux motors offer huge advantages in diameter scaling. Their performance increases much more with rotor diameter compared to traditional radial flux motors, enabling greater torque and efficiency without increasing weight.

EFFICIENT AND COST EFFECTIVE

Improved efficiency minimises energy consumption, while modularity ensures scalable performance and system flexibility across use cases.

HIGHER TORQUE DENSITY THAN RADIAL FLUX

Maximise performance in compact and lightweight designs. Axial flux motors can deliver up to 30% more torque than radial flux motors in the same space.

SUPERIOR POWER-TO-WEIGHT RATIO

Axial Flux Motors excel with their remarkable power-to-weight ratio.

COMPACT AND SPACE EFFICIENT

Perfect where size matters, fitting more power into less space.

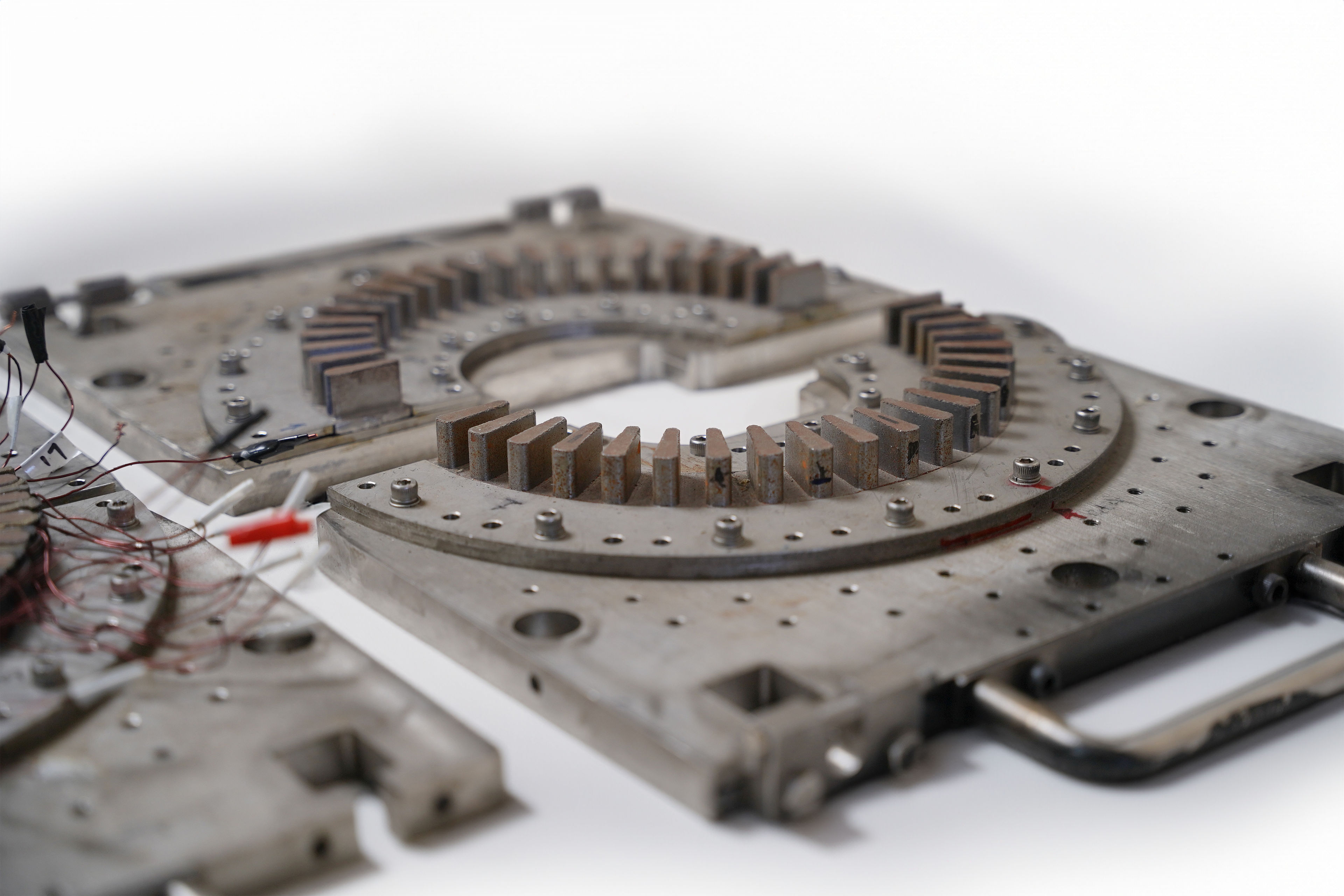

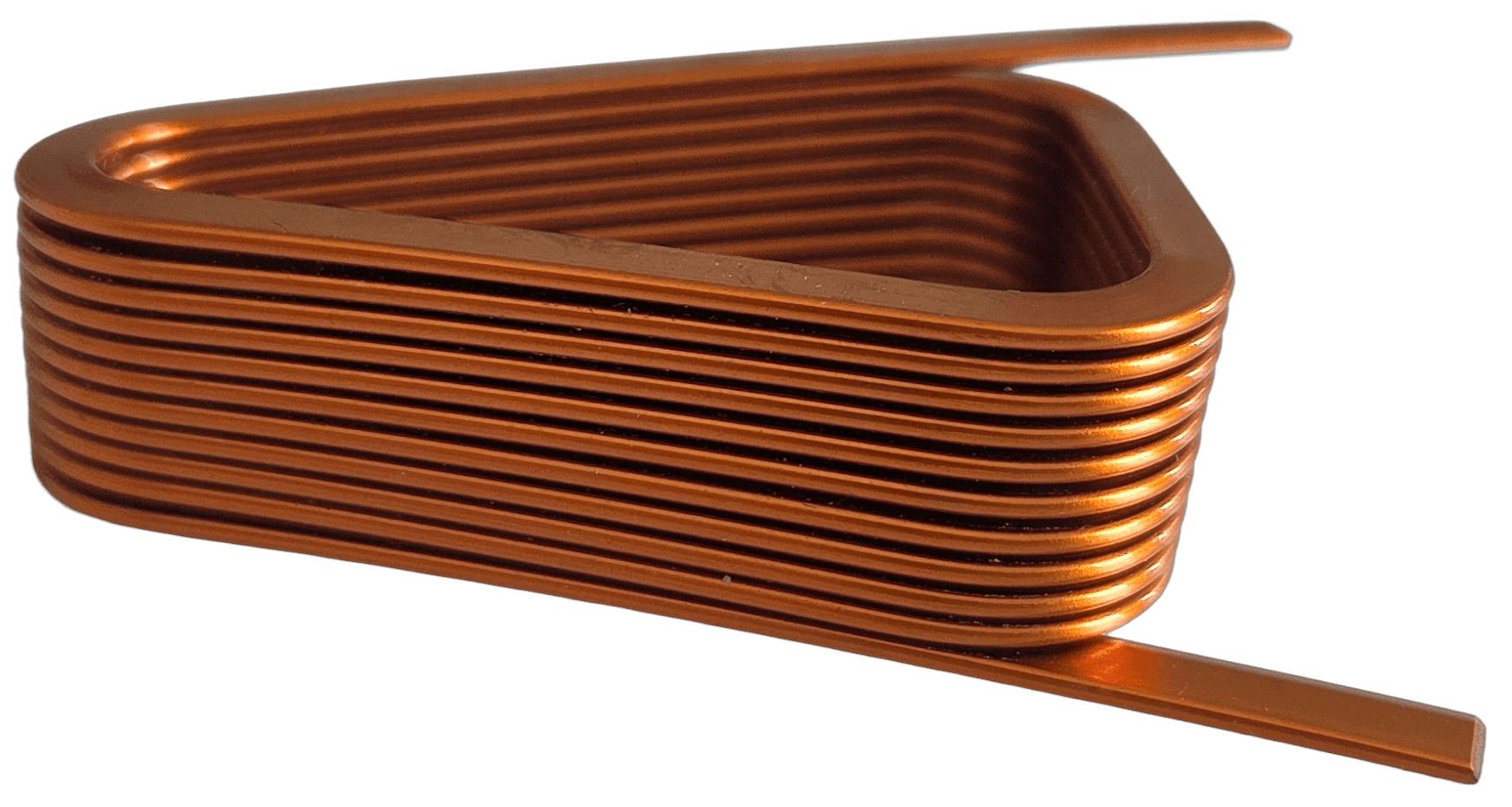

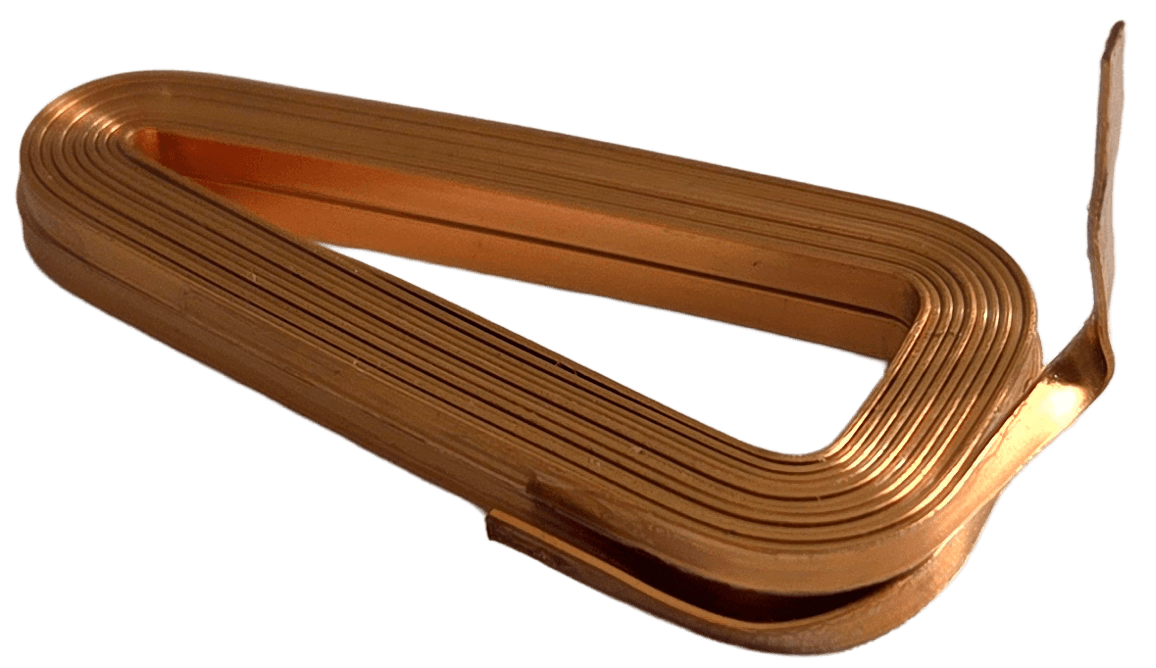

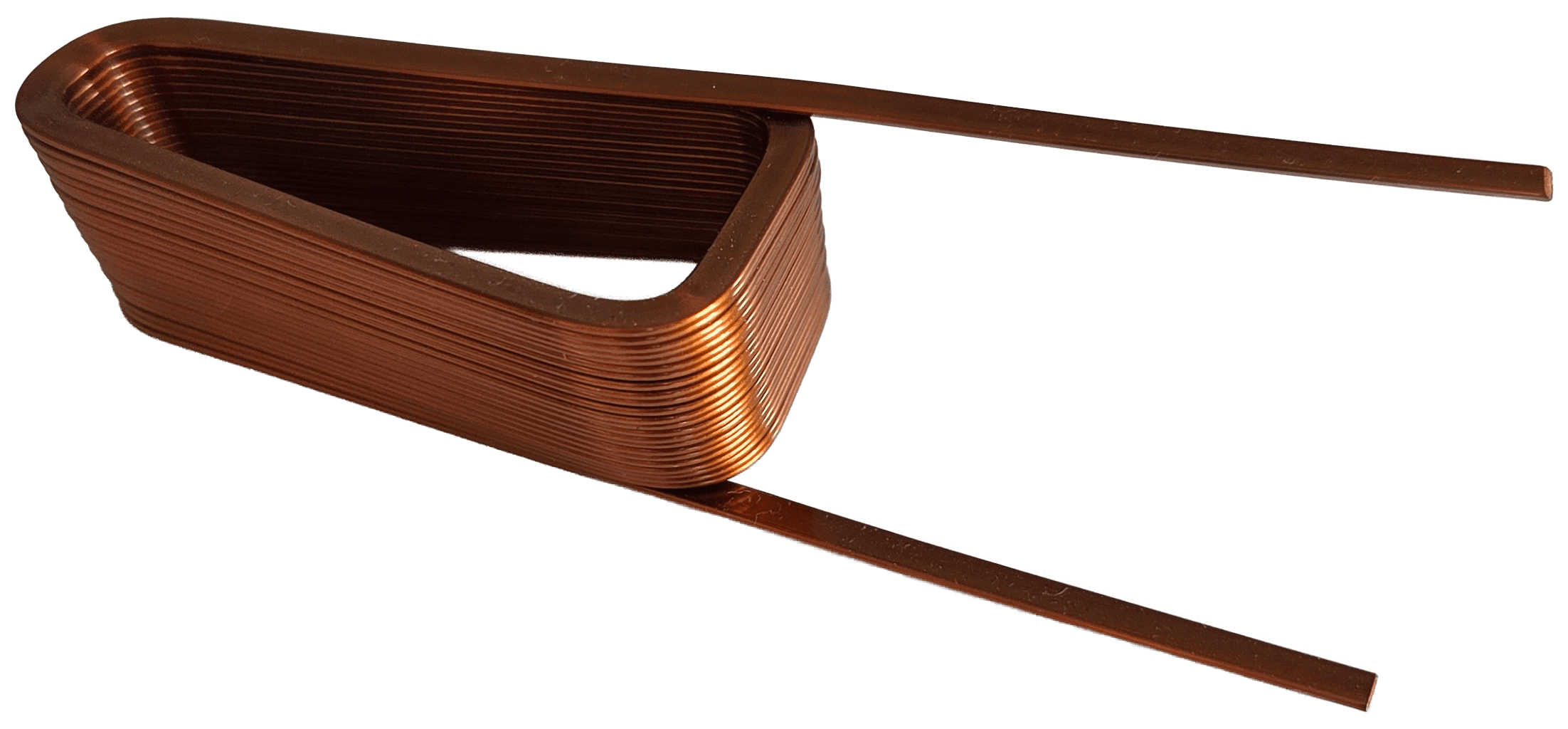

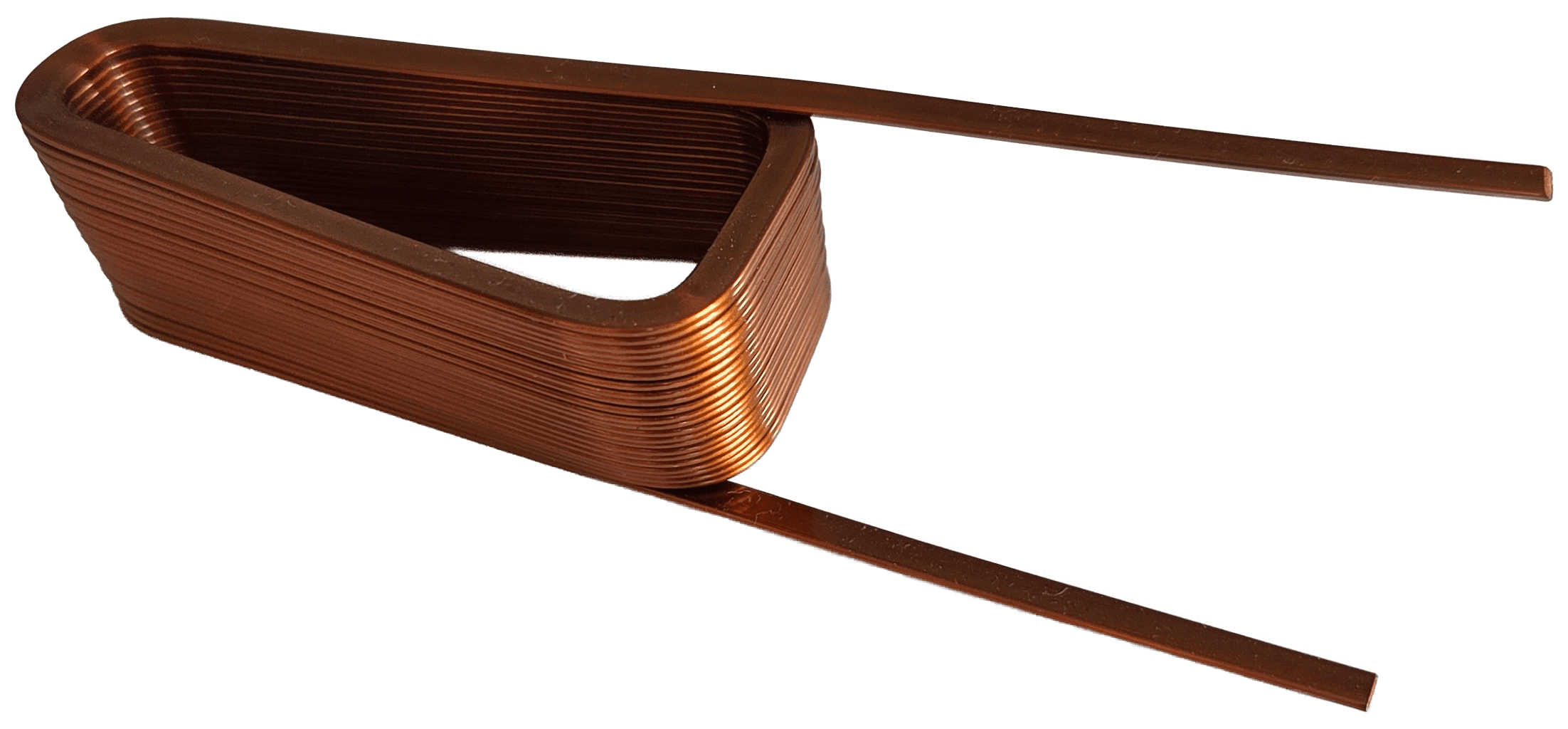

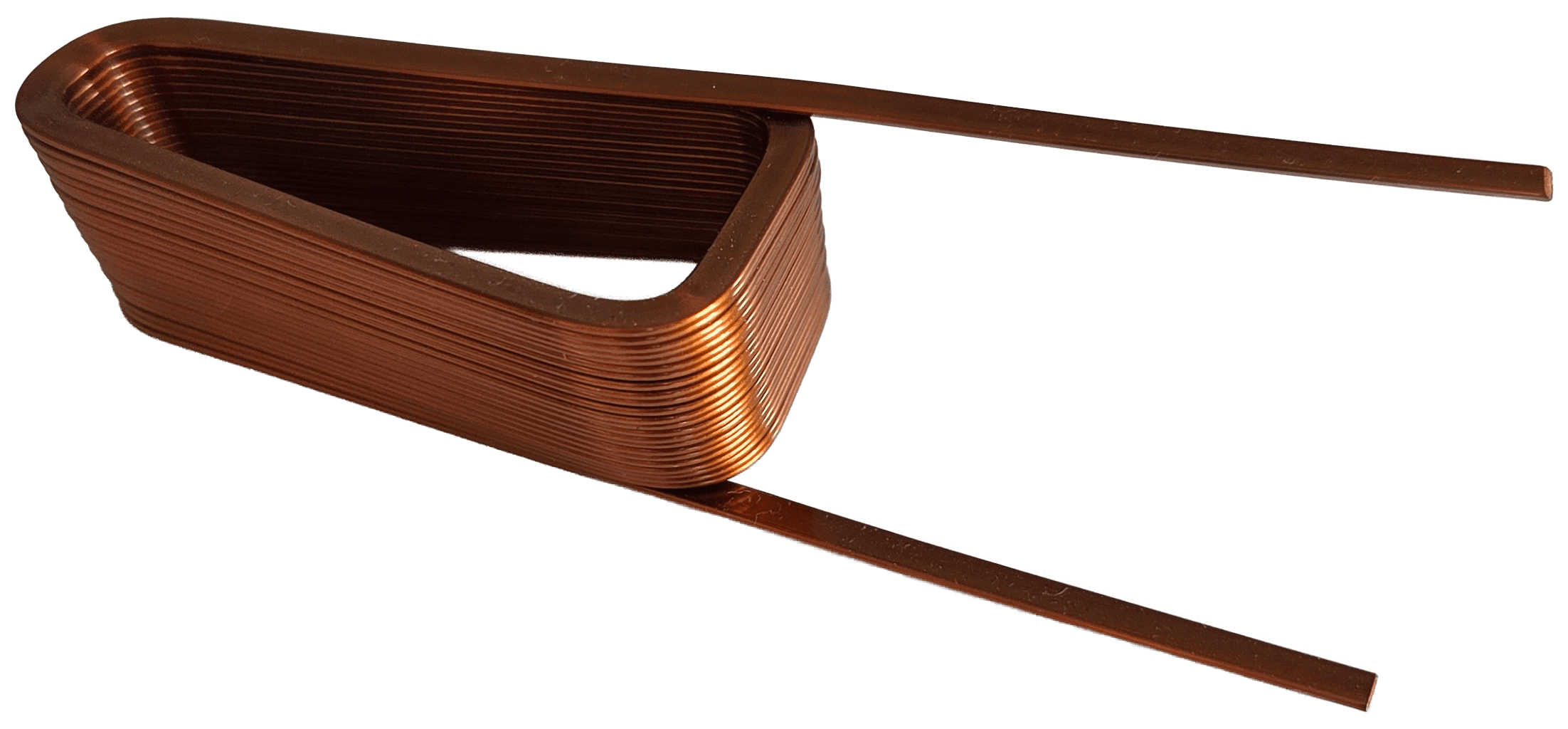

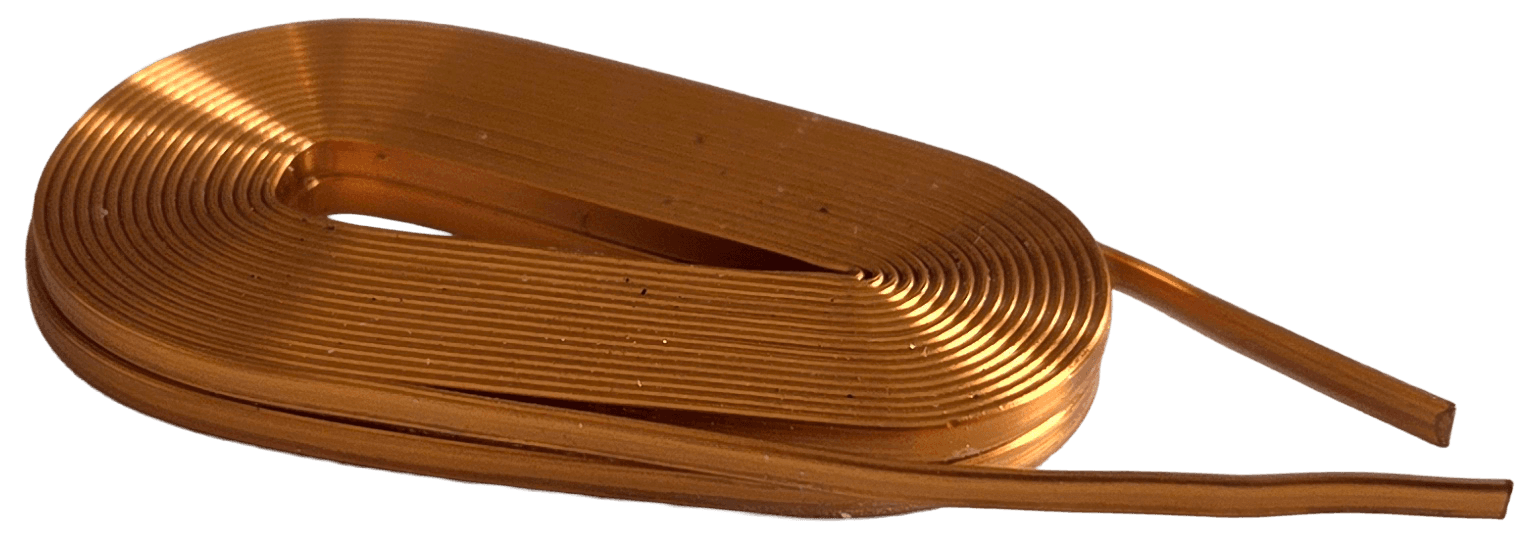

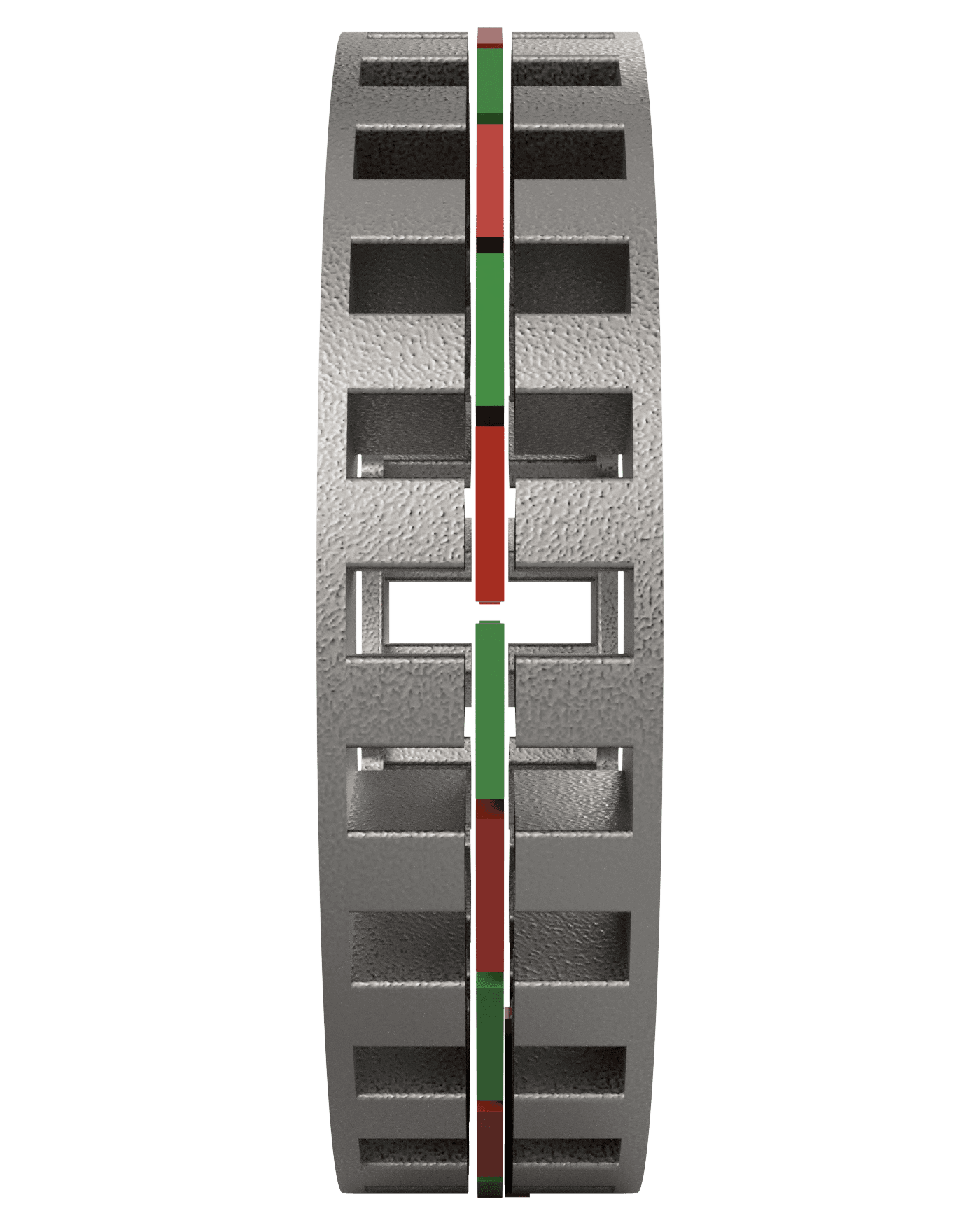

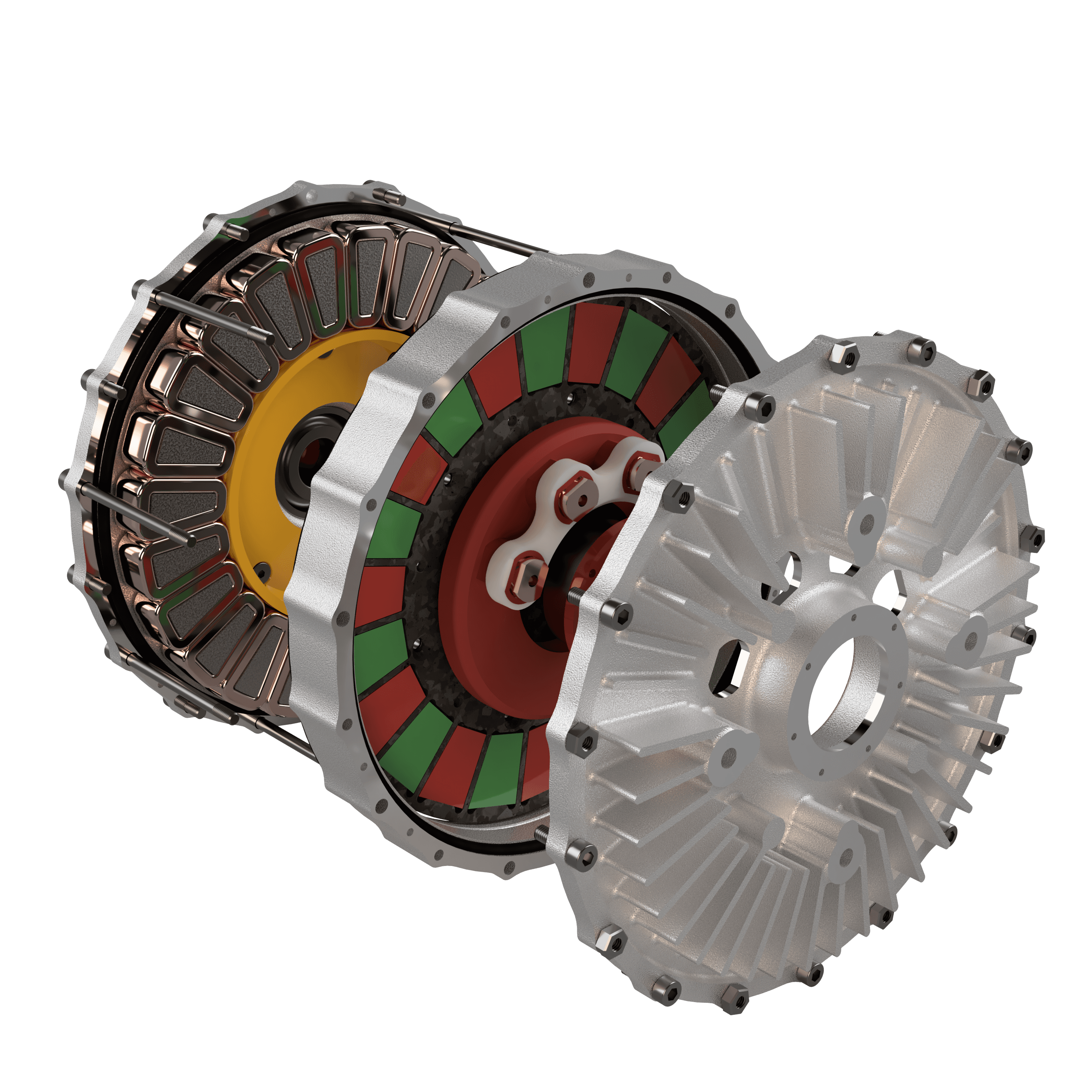

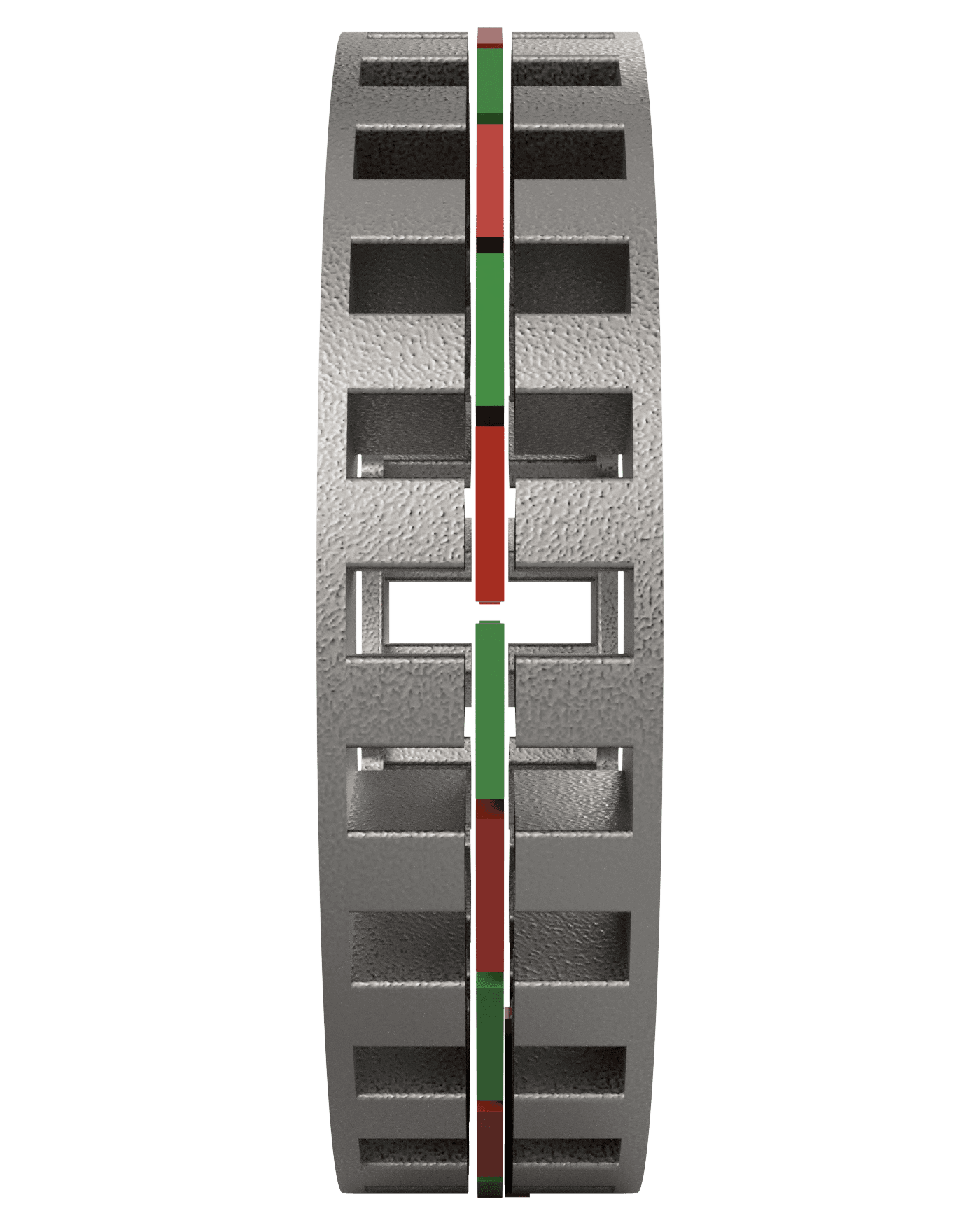

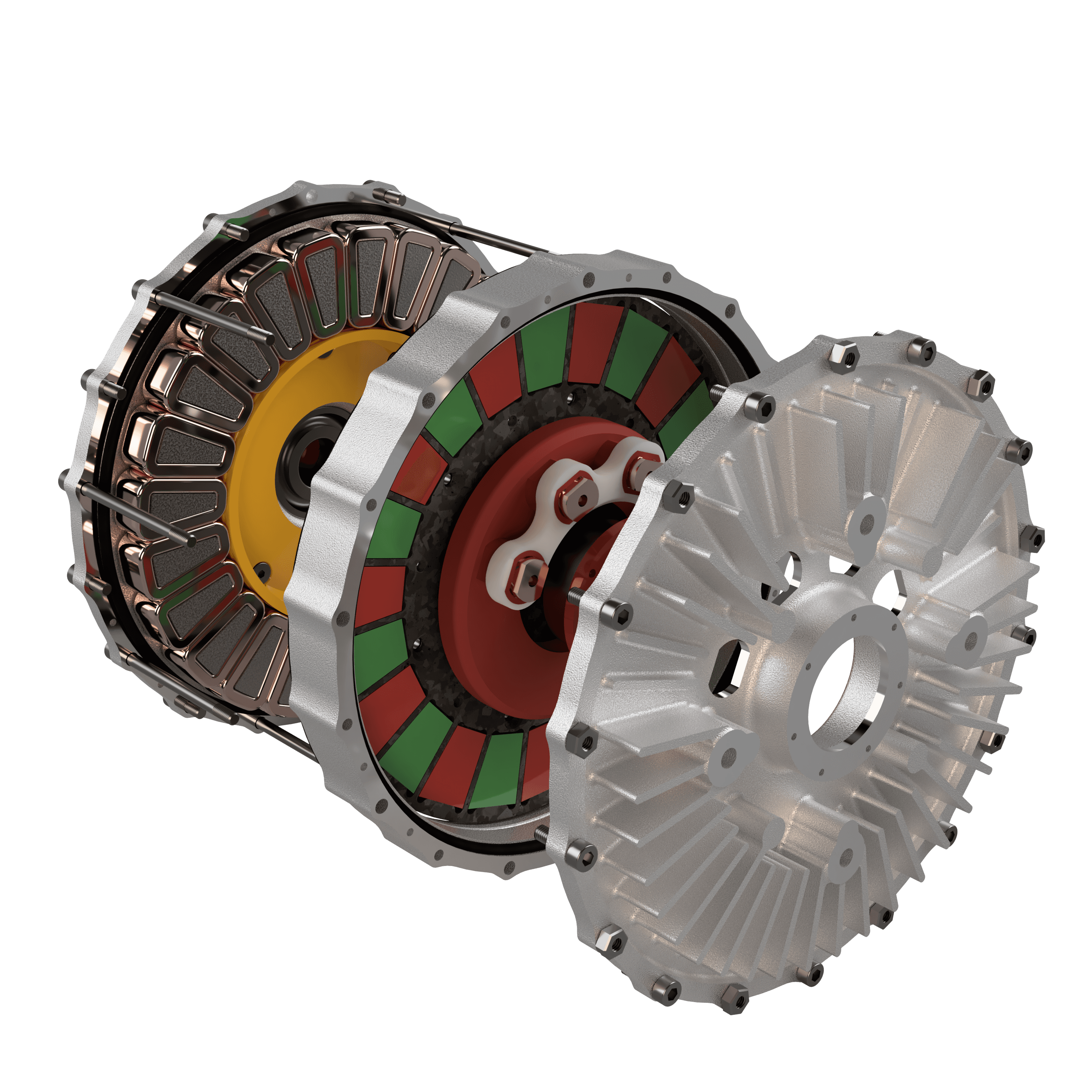

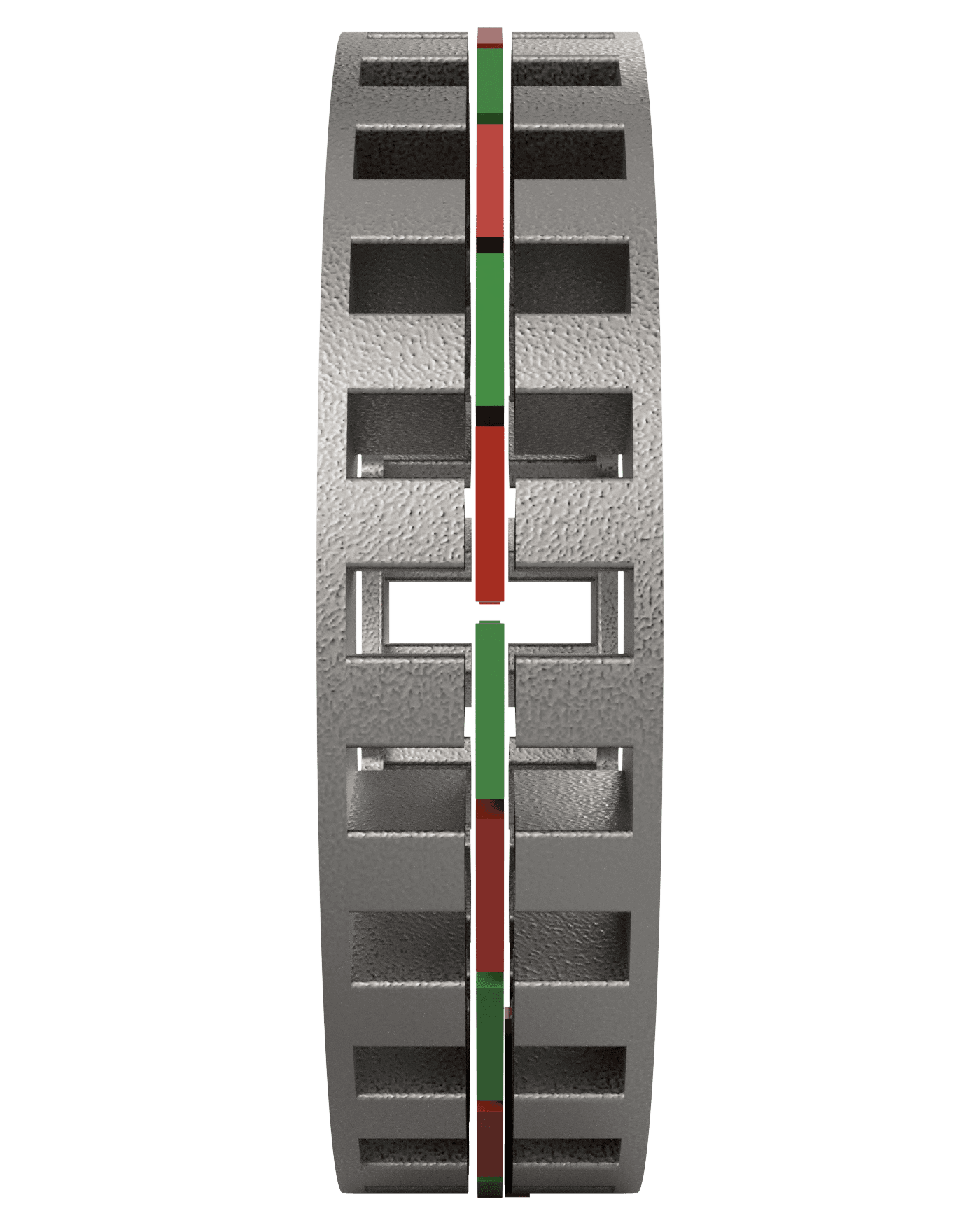

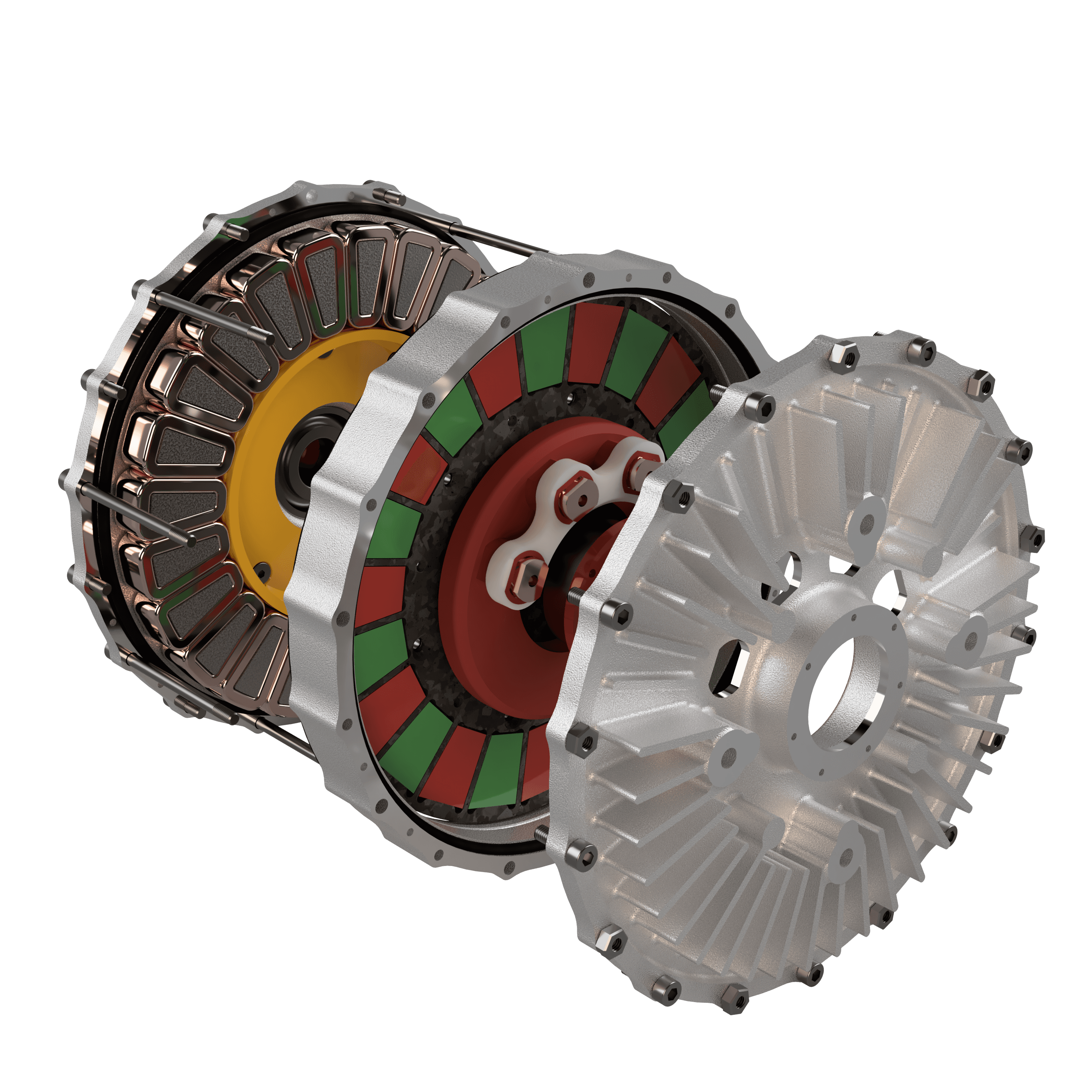

How Do Axial Flux Motors Work

NEXT GEN TECHNOLOGY

Axial flux motors are electric motors in which magnetic flux runs along the shaft axis (not radially). A flat ring of magnets faces a flat ring of copper coils across a tiny gap, so the motor can be short yet wide in diameter.

When electricity flows in the coils, the magnets pull and push in a circle, the way you twist a jar lid. That circular pull makes the disk spin smoothly and gives strong turning force from a compact, lightweight shape.

WHERE THEY SHINE

In industry, these motors help cut electricity costs due to its efficiency. On the water, their sealed, quiet, direct-drive setup suits marine propulsion with fewer moving parts. Off-highway equipment benefits from durable, high-torque drives that can even replace hydraulics in tight spaces.

Why Axial Flux Technology

HIGHER TORQUE AND POWER DENSITY IN A MORE COMPACT PACKAGE

The axial flux technology is reshaping the landscape of electric motors. Even with improved material usage, it outperforms radial flux motors, making it an ideal choice where packaging and performance matters.

PERFORMANCE INCREASES MUCH MORE WITH ROTOR DIAMETER

Axial flux motors offer huge advantages in diameter scaling. Their performance increases much more with rotor diameter compared to traditional radial flux motors, enabling greater torque and efficiency without increasing weight.

EFFICIENT AND COST EFFECTIVE

Improved efficiency minimises energy consumption, while modularity ensures scalable performance and system flexibility across use cases.

HIGHER TORQUE DENSITY THAN RADIAL FLUX

Maximise performance in compact and lightweight designs. Axial flux motors can deliver up to 30% more torque than radial flux motors in the same space.

SUPERIOR POWER-TO-WEIGHT RATIO

Axial Flux Motors excel with their remarkable power-to-weight ratio.

COMPACT AND SPACE EFFICIENT

Perfect where size matters, fitting more power into less space.

How Do Axial Flux Motors Work

NEXT GEN TECHNOLOGY

Axial flux motors are electric motors in which magnetic flux runs along the shaft axis (not radially). A flat ring of magnets faces a flat ring of copper coils across a tiny gap, so the motor can be short yet wide in diameter.

When electricity flows in the coils, the magnets pull and push in a circle, the way you twist a jar lid. That circular pull makes the disk spin smoothly and gives strong turning force from a compact, lightweight shape.

WHERE THEY SHINE

In industry, these motors help cut electricity costs due to its efficiency. On the water, their sealed, quiet, direct-drive setup suits marine propulsion with fewer moving parts. Off-highway equipment benefits from durable, high-torque drives that can even replace hydraulics in tight spaces.

Why Axial Flux Technology

HIGHER TORQUE AND POWER DENSITY IN A MORE COMPACT PACKAGE

The axial flux technology is reshaping the landscape of electric motors. Even with improved material usage, it outperforms radial flux motors, making it an ideal choice where packaging and performance matters.

PERFORMANCE INCREASES MUCH MORE WITH ROTOR DIAMETER

Axial flux motors offer huge advantages in diameter scaling. Their performance increases much more with rotor diameter compared to traditional radial flux motors, enabling greater torque and efficiency without increasing weight.

EFFICIENT AND COST EFFECTIVE

Improved efficiency minimises energy consumption, while modularity ensures scalable performance and system flexibility across use cases.

HIGHER TORQUE DENSITY THAN RADIAL FLUX

Maximise performance in compact and lightweight designs. Axial flux motors can deliver up to 30% more torque than radial flux motors in the same space.

SUPERIOR POWER-TO-WEIGHT RATIO

Axial Flux Motors excel with their remarkable power-to-weight ratio.

COMPACT AND SPACE EFFICIENT

Perfect where size matters, fitting more power into less space.

How Do Axial Flux Motors Work

NEXT GEN TECHNOLOGY

Axial flux motors are electric motors in which magnetic flux runs along the shaft axis (not radially). A flat ring of magnets faces a flat ring of copper coils across a tiny gap, so the motor can be short yet wide in diameter.

When electricity flows in the coils, the magnets pull and push in a circle, the way you twist a jar lid. That circular pull makes the disk spin smoothly and gives strong turning force from a compact, lightweight shape.

WHERE THEY SHINE

In industry, these motors help cut electricity costs due to its efficiency. On the water, their sealed, quiet, direct-drive setup suits marine propulsion with fewer moving parts. Off-highway equipment benefits from durable, high-torque drives that can even replace hydraulics in tight spaces.

SIGN UP TO OUR NEWSLETTER

SIGN UP TO OUR NEWSLETTER